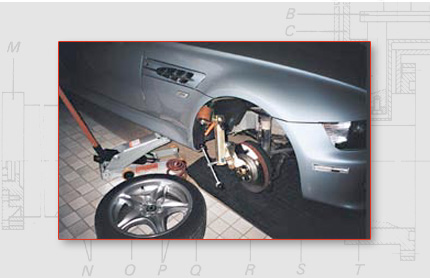

| Loosen

the wheel and remove it from the wheel spindle. Thoroughly clean the inside

of the mudguard and edge of the wheel arch; remove loose skid plate and

other loose parts e.g. split etc. Secure the FenderRoller to the wheel

spindle flange with the original wheel bolts or nuts. The wheel guard

should be moved in several stages. For example, first by 30 degrees, then

60, then 90. The FenderRoller can be adjusted in one go by loosening the

upper clamping lever. During this process, the area to be worked should

be heated thoroughly using a hot air gun (c. 40-60°C). The FenderRoller

can be adapted to suit different wheel guard radii and wheel arches by

adjusting the telescope and twisting the spindle. If the Fender Roller

is used properly, you will then have a smooth beaded edge without lasting

damage to the varnish. After the beading process is completed, the inside

edges of the wheel arches should be sealed with an appropriate car body

jointing compound and car body protective coating.

|